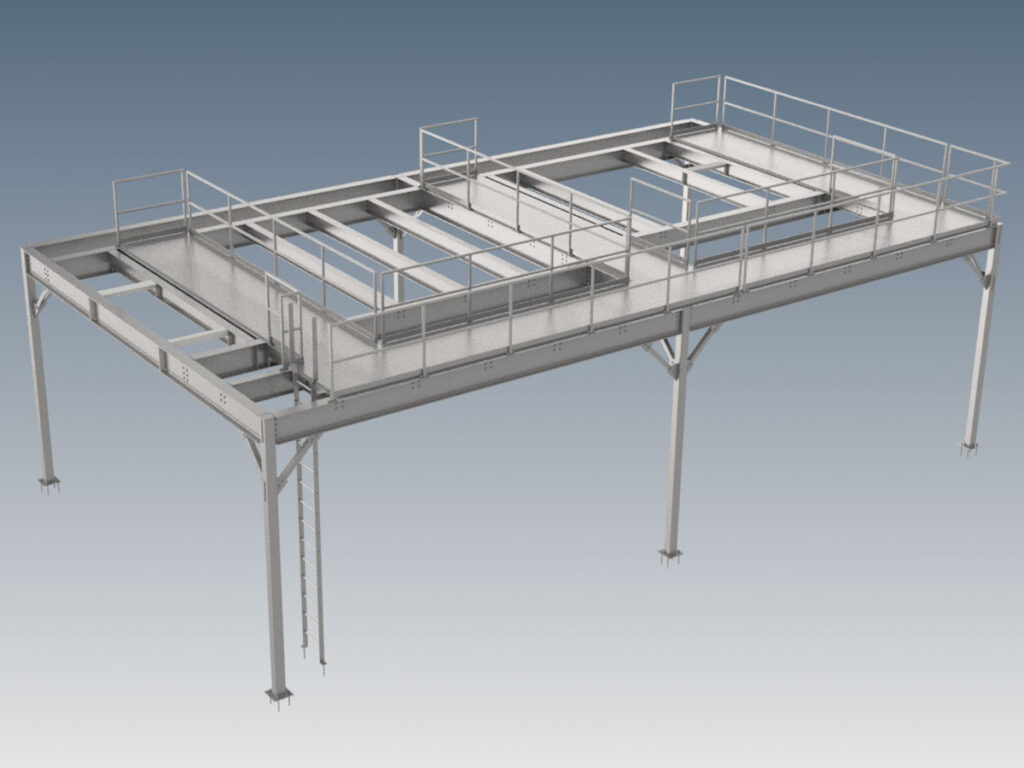

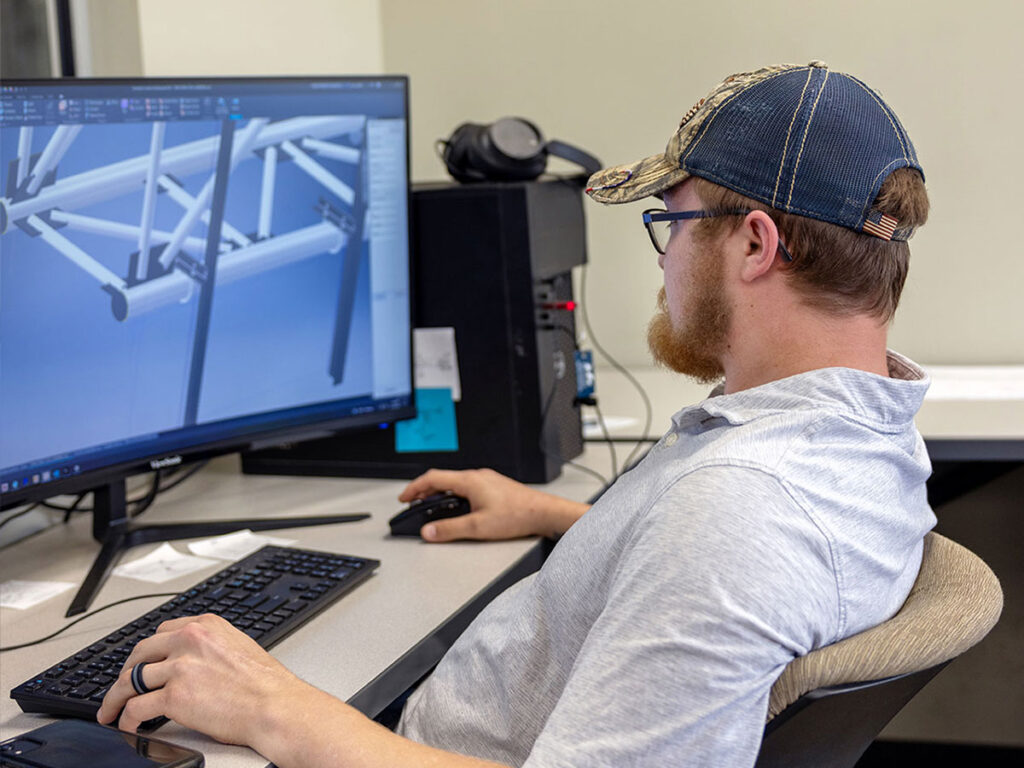

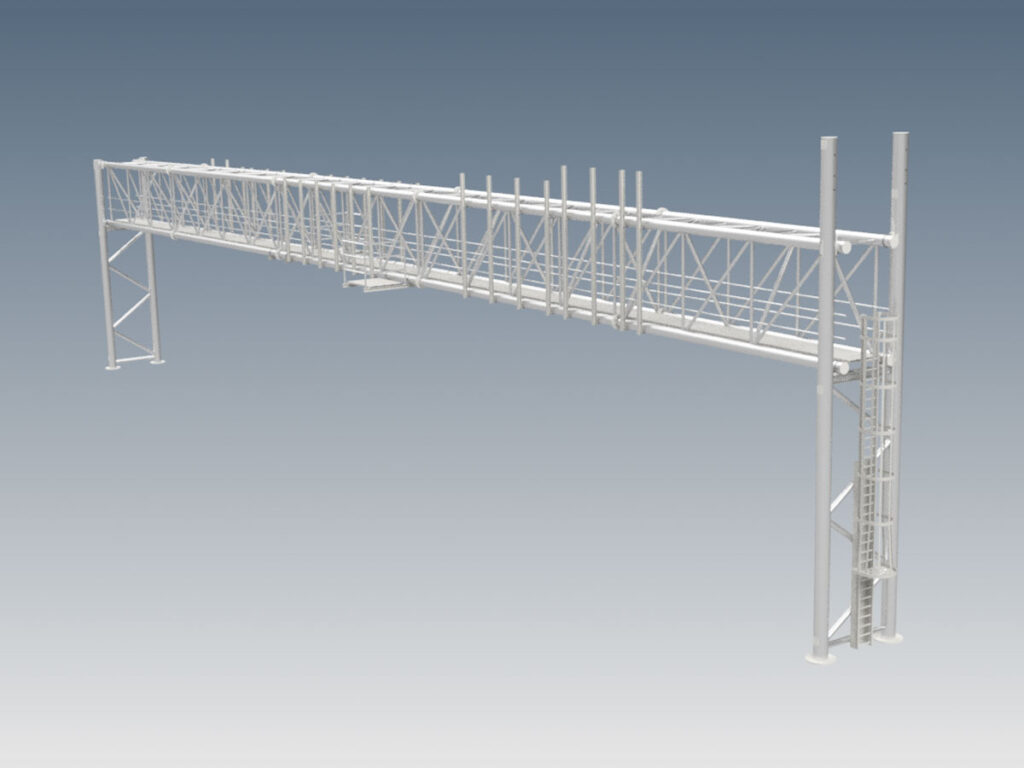

CAD Design & Engineering

Using various softwares, we build 3D models in house for each product or project to identify conflicts and ensure accuracy. Shop drawings are then produced from these models to your exact specifications. We also have the resources to produce engineering calcs and stamped drawings.

Material Procurement

Thanks to our geographic location in the heart of the United States and many longstanding relationships, we hold a competitive advantage when it comes to sourcing material. Metal Pros regularly procures, fabricates, and welds carbon steel, aluminum, and stainless steel.

Fabrication

Plasma cutting up to 3” thick, oxy torch capabilities up to 8” thick, drilling, milling, beveling, and scribing, all on one machine.

Waterjet cutting up to 8” thick, with the ability to cut metal, plastic, granite, glass, and wood.

Tube and shape plasma processing centers for speed and precision.

CNC beamline drilling, bandsaw cutting, bending, rolling, milling, and punching also performed in house.

Welding

Metal Pros staffs a full weld shop with certifications to D1.1, D1.2, D1.6, & ASME. We weld carbon steel, aluminum, and stainless steel.

Quality Control

With (2) CWI’s and an ASNT NDE Level II MT, UT, & PT on staff, you can rest assured your finished product will meet your quality standards. Metal Pros is certified annually by the American Institute of Steel Construction (AISC), as well as ISO 9001, and various State Departments of Transportation.

Finishes

Metal Pros has great relationships with service vendors throughout the Midwest. We offer galvanizing, anodizing, painting, & powder coating finishes for a turnkey product.